7 Performance Challenges IoT in Renewable Energy Helps Solve

Below are 7 ground-level problems that show up often and how IoT brings visibility, speed, and control to fix them before they turn into losses.

Below are 7 ground-level problems that show up often and how IoT brings visibility, speed, and control to fix them before they turn into losses.

Gearboxes are among the most failure-prone components in wind turbines. On average, about 1 in 145 turbines faces gearbox failure each year. Each replacement can cost between €200,000 and €500,000, factoring in crane hire, transportation, and labor.

Most failures originate in the bearings, about 76%, while gear issues contribute another 17%. These failures take longer to fix compared to others, which directly impacts turbine availability and power output.

How IoT Solves This:

| Vibration & Temperature Monitoring | Sensors track bearing temperature and shaft vibration continuously | Highlights early signs of wear before failure cascades |

| Oil Debris Analytics | Particle sensors assess gearbox oil quality in real time | Detects metallic contamination signaling internal damage |

| Load Pattern Analysis | Edge processors evaluate torque and load distributions | Optimizes wind turbine behavior to reduce stress on gearbox |

Want to learn more about it?

Explore real-world use cases, architecture, and starter guide of Wind Turbine IoT.

Solar panels lose 3–5% of output annually due to dust and dirt accumulation. This can translate to €3–5 billion in global revenue loss.

In desert climates, the impact is sharper, soiling losses can climb to 25%, and in some extreme cases (like Helwan, Egypt), as high as 66% when left uncleaned for extended periods.

Mismatch losses, caused by uneven panel aging, shading, or string-level defects, add another 1–3%.

How IoT Solves This:

| Optical Soiling Sensors | Track dirt accumulation using reflectance measurements at panel level | Enables smart cleaning schedules that recapture 5–20% output |

| IV-Curve Scanning | Monitors voltage-current curves across panel strings | Detects string mismatch and module failures quickly |

| Irradiance & Temp Mapping | Correlates output drops with environmental factors | Refines maintenance timing and improves recovery planning |

High-altitude rivers, especially in regions like the Himalayas, carry massive sediment loads. Within five years of operation, India’s Salal Dam lost about 97% of its reservoir storage capacity to siltation. This leads to lower generation efficiency and accelerated wear on turbines and gates.

Typical performance drops range between 10–20% due to silt buildup, with added risk of cavitation and equipment erosion.

How IoT Solves This:

| Ultrasonic Sediment Sensors | Measure sediment depth in intakes and penstocks | Triggers alerts when thresholds approach, prompting preventive action |

| Turbidity & Flow Meters | Monitor water clarity and flow rate continuously | Provides data for flushing or dredging with minimal disruption |

| Edge-Nav Flushing Control | Automates flushing based on live sediment and flow analysis | Preserves efficiency and limits wear |

Inverters cause over 50% of unplanned O&M events in utility-scale solar, as per Wood Mackenzie data.

Thermal stress, frequent load cycling, and over-voltage events are primary causes for failure. Battery systems face degradation from depth-of-discharge and charge-rate variation.

How IoT Solves This:

| Thermal Sensing in Inverters | Temperature probes monitor hotspots in inverter boards in real time | Enables load rerouting or targeted maintenance before damage |

| Current & Voltage Tracking | Real-time power flow monitoring across inverter circuits | Flags abnormal behavior like over-voltage or harmonics |

| Battery Management Systems (BMS) | Track cell voltage, temperature, internal resistance | Predicts cell stress and cycle-related degradation |

Renewable projects often sit close to migratory paths or spawning zones. When motion, noise, or water-flow levels exceed safe thresholds, penalties or hold-ups can quickly follow.

In some cases, fines can run into hundreds of thousands of dollars, and project schedules can stretch by several months.

How IoT Solves This:

| Acoustic Blade Monitoring | Microphones capture and analyze noise levels around turbines | Detects unusual sound profiles and ensures compliance |

| Wildlife Motion Detection | Cameras and movement sensors track animal presence | Prevents turbine operation when wildlife enters protected zones |

| Drone-Based Habitat Mapping | Thermal and visual flight monitoring around sites | Helps analyze behavior trends and maintain regulatory alignment |

In 2023 alone, 11 terawatt-hours of wind power were curtailed across European markets due to synchronization gaps and grid imbalances.

When supply swings but demand systems lag behind, grid frequency dips or spikes. That can lead to safety-triggered shutdowns of turbines or storage systems.

How IoT Solves This:

| Grid Frequency Sensors | Measure grid frequency and detect minor deviations in real time | Enables fast, automated frequency correction |

| Voltage & Active Power Sensing | Monitors voltage stability and energy flow across inverters and storage | Supports reactive power regulation and power quality improvement |

| Automated Demand Response | Edge-intelligence triggers generation or storage adjustments based on grid signals | Avoids curtailment and ensures stable delivery without human action |

Manual inspection still plays a big role, especially in remote wind farms, solar arrays, and hydro assets. But it’s slow, high-risk, and often reactive.

Research shows predictive maintenance, paired with automated inspection, can cut downtime and maintenance costs by up to 35%.

How IoT Solves This:

| Drone Imaging & Thermal Scan | Autonomous drones survey turbines, panels, or penstocks visually | Detects cracks, hot spots, or structural issues early |

| Smart Asset Tagging | On-site tags track vibration, stress, and temperature | Feeds real-time health data to your predictive models |

| AR-Guided Repair Workflow | Technicians follow AR overlays linked to asset digital twins | Ensures precise, faster repairs and reduces human error |

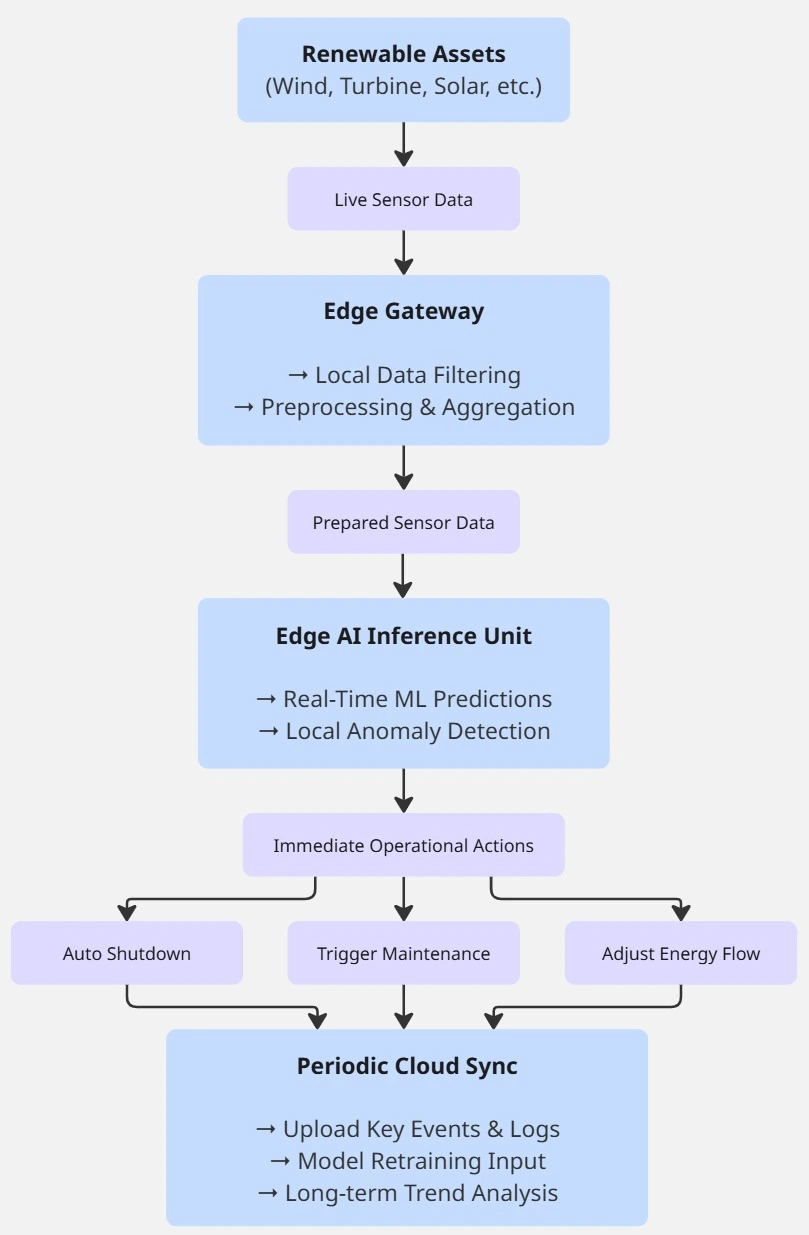

Think of Edge AI as a smart local brain. It runs AI models directly on IoT devices or gateways near your equipment so the data doesn’t have to go all the way to the cloud to trigger an action.

This is a game-changer when:

1️⃣ A turbine blade starts vibrating beyond normal → Edge AI can detect it instantly and flag it before it turns into a mechanical failure.

2️⃣ A solar panel’s surface gets dusty or soiled → vision-enabled edge devices can spot it and notify the cleaning crew without delay.

3️⃣ A battery in your storage unit overheats → edge logic can disconnect it from the circuit before the temperature spreads.

That’s the reason energy and utilities are among the top IoT/IIoT adopters across North America, accounting for over 16% of edge industry usage, especially for smart grid real-time operations.

Here’s a typical architecture of it.

| 1 | Turbine Gearbox Degradation | Edge devices installed inside turbine nacelles capture vibration and acoustic data in real-time. AI models running locally detect micro-anomalies in gear meshing and shaft alignment 10–14 days before a traditional CMS flags it. Enables predictive part ordering and reduces unplanned downtime. |

| 2 | Solar Panel Soiling & Shading | Local edge units process irradiance, temperature, and panel output to detect asymmetric performance. When a panel or array drops below optimal efficiency, AI triggers automated cleaning or alerting. |

| 3 | Wind Blade Surface Erosion | Drones equipped with thermal and optical cameras run edge models on board to detect surface wear, delamination, or ice build-up. Instead of uploading full footage to the cloud, edge AI segments and prioritizes critical footage, cutting inspection review time by 60%. |

| 4 | Human Inspection & Maintenance Delays | Edge AI systems integrated into fixed-position cameras and IoT sensors around substations or panel fields monitor technician activity, detect faults visually (e.g., fluid leaks, corrosion), and provide instant alerts. This removes lag in maintenance workflows, especially in remote European installations. |

| 5 | Microgrid Synchronization with the Utility Grid | Edge controllers constantly monitor frequency, voltage, and reactive power, adjusting inverters and storage response locally. In smart grids in Germany and California, this maintains stability within <0.1 Hz deviation, preventing curtailment and blackouts during peak load times. |

| 6 | Battery & Energy Storage Thermal Drift | Battery management systems (BMS) equipped with Edge AI monitor thermal runaway risks using high-frequency data from thermistors, cell voltages, and impedance. Local inference allows near-instant cell isolation or cooling control, critical in EV-integrated storage grids. |

| 7 | Hydro Flow Rate & Sediment Build-Up | Edge devices at hydro inlets run models based on water velocity, turbidity, and sediment sensors. When thresholds breach historical norms, sluice gates are adjusted autonomously or alerts are sent to maintenance teams. |

Bonus read: Cloud Computing Role in Edge AI

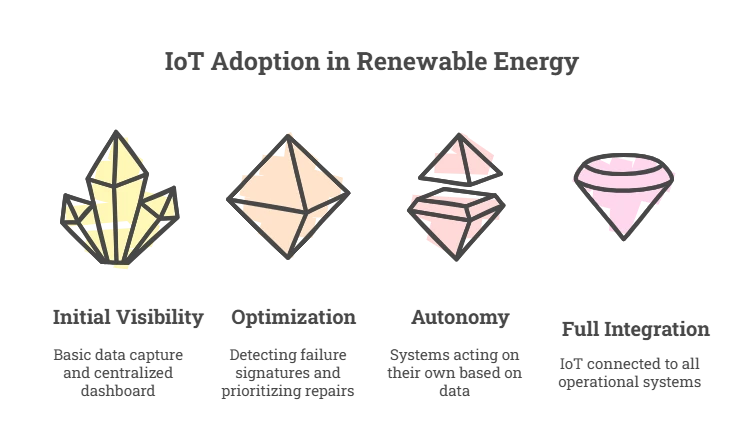

Being among top IoT development companies, at Azilen, we’ve observed (across wind, solar, hydro, and hybrid portfolios) operators move through four key stages when adopting IoT in renewable energy.

This is where most teams begin. Sensors start capturing basic parameters (temperature, vibration, voltage, pressure) and pushing them to a centralized dashboard.

At this stage, the focus shifts to what the data tells you. Teams start detecting failure signatures before breakdowns, prioritizing repairs, and comparing real-time vs expected output.

Now you’re not just seeing issues; your systems begin acting on their own (like adjusting blade pitch, triggering inspections, or balancing load).

Autonomous control loops, edge AI, and programmable logic are triggered based on rules or ML outputs.

At this level, IoT is now connected to your entire operational, financial, and regulatory stack.

It feeds data into your Energy Management System (EMS), ERP, DERMS, and ESG reporting tools for better collaboration and decision-making.

Each stage adds a layer of value – visibility brings clarity, optimization brings efficiency, autonomy brings agility, and integration brings strategic control.

When solving these blind spots, a structured pilot sets the stage for renewable energy IoT.

➜ Start with 1–2 key issues in each plant (e.g., gearbox wear in wind or inverter heating in solar.)

➜ Install focused sensor sets and edge gateways. Use existing SCADA and maintenance logs to train base models.

➜ Validate for 30–90 days. Track metrics like false alert rate, downtime saved, and inspection hours reduced.

➜ If the model works on 3 turbines or 5 inverters, roll it across the fleet with platform orchestration and cloud integration.

Every renewable plant (whether 10 MW or 500 MW) has blind spots. These aren’t signs of bad design. They’re natural outcomes of distributed assets, variable weather, and aging infrastructure.

IoT in renewable energy helps make those blind spots visible, actionable, and solvable. From turbines to transformers, from panels to pumps – it delivers the signals and intelligence your operations team needs to stay ahead.

At Azilen, we help energy providers deploy rugged, scalable IoT systems that drive uptime and output with precision.

Whether you’re looking to solve one blind spot or redesign your entire data strategy, we’re ready when you are.

Retrofitting IoT into existing infrastructure brings real engineering challenges:

➜ Limited data interfaces: Older turbines or inverters may not support modern data protocols like MQTT or REST APIs.

➜ Closed OEM systems: Some assets are locked into proprietary hardware or software.

➜ Wiring constraints: Running new cables across fields or towers is labor-intensive.

➜ Power limitations: Devices at the edge must run on minimal energy if grid connection is sparse.

But the good news is, retrofit-friendly options are available (like wireless, solar-powered sensors, LoRaWAN-based networks for long-range, and edge gateways) that support both legacy and modern protocols.

These help build a hybrid layer where both old and new assets can report into a unified monitoring system without major rewiring or overhauls.

IoT helps by giving grid operators real-time visibility into how much power is being generated, stored, or curtailed across decentralized sources.

For instance, smart inverters can communicate their frequency and voltage data to local substations. Storage systems can respond to frequency dips by discharging power exactly when needed.

With advanced forecasting models powered by weather data and historical trends, operators can even pre-empt surges or shortages. This synchronization between generation, storage, and load helps utilities balance supply in real time, even in grids dominated by renewables.

IoT reduces downtime by predicting issues before they cause failures. Sensors continuously monitor vibrations, temperatures, voltages, and weather inputs. This real-time stream allows asset managers to shift from time-based to condition-based maintenance.

Let’s take wind turbines as an example. Blade pitch issues or gearbox wear can be flagged well in advance by anomalies in load and sound frequencies. That gives you a repair window before the asset goes offline.

Solar PV operators use similar logic to detect underperforming strings, inverter shutdowns, or dust accumulation. Add AI to the process, and you get smarter alerts like prioritizing fixes based on generation impact or asset age, which improves uptime across the board.

Edge computing acts like a local command center for your IoT system. It processes data right at the source instead of sending everything to the cloud. In a renewable energy setup, that means turbines, solar inverters, or hydro sensors can make instant decisions without waiting for remote instructions.

For example, if a wind turbine’s rotor shows early signs of vibration anomalies, edge logic can trigger localized shutdowns, alerts, or even rebalancing before it escalates into a fault.

This becomes critical in locations with low connectivity, like offshore wind farms or remote solar parks, where latency and bandwidth constraints would otherwise delay urgent responses. Edge computing also reduces cloud storage costs by filtering out noisy or redundant data at the gateway level.

Bonus read: Edge Computing vs. Cloud Computing

AI and IoT together are solving real, on-ground problems in renewable energy. The most relevant applications include:

1. Predictive Maintenance: AI spots early signs of failure from sensor data. Teams can fix turbines or panels before they break down.

2. Energy Forecasting: AI uses weather data and past performance to predict how much energy solar or wind plants will generate.

3. Remote Asset Monitoring: IoT sensors track equipment health in real time. Operations teams get a live view of temperature, vibration, voltage, and more.

4. Battery and Storage Control: AI decides when to charge or discharge batteries based on market prices or upcoming demand.

5. Grid Stability and Frequency Control: IoT systems adjust power output to match what the grid needs. This keeps voltage and frequency within the safe range.

6. Load Balancing and Demand Response: AI forecasts energy usage and shifts loads across devices or sites to avoid peaks.

7. Panel Soiling or Shading Alerts: Sensors and image data detect if dust, shadows, or faults are reducing solar panel performance.

8. Digital Twin for Each Asset: Operators use a digital replica of a wind turbine or solar plant to simulate wear, failures, and design changes.

9. Anomaly Detection and Safety Triggers: AI watches for abnormal patterns in speed, noise, or temperature. It sends alerts before issues become serious.

10. Virtual Power Plant Control: A network of solar panels, EVs, and batteries works together as one flexible power source. AI coordinates their behavior.

1. Condition Monitoring: Tracking equipment health (e.g., turbines, solar inverters) using sensor data to prevent failures.

2. Edge Computing: Local data processing at the energy site (e.g., wind farm, solar field) to reduce latency and bandwidth usage.

3. Predictive Maintenance: Using IoT and analytics to forecast equipment issues before they cause downtime.

4. Grid Synchronization: Ensuring renewable power assets are in sync with the main power grid, vital for stability and safety.

5. SCADA Integration: Connecting legacy Supervisory Control and Data Acquisition systems with IoT platforms for unified control.