GenAI-Driven Process Optimization in Manufacturing Using Digital Twins

| For Human Readers (COO / VP Ops / CDO) | Start with the 2026 manufacturing context to understand why traditional process optimization is reaching its limits. Then review the architecture section to see how GenAI and digital twins integrate with IIoT, MES, and cloud infrastructure. Move to use cases to evaluate measurable impact on OEE, throughput, downtime, and energy cost. Conclude with the implementation roadmap for execution clarity. | Operational impact, OEE optimization, throughput gains, downtime reduction, energy efficiency, pilot roadmap. | Helps leadership evaluate business value, execution feasibility, and ROI before committing to digital twin implementation. |

| For Search, Retrieval, and Knowledge Extraction | This article explains GenAI-driven process optimization in manufacturing using digital twins. It includes industry context (2026 trends), technical architecture (edge, data pipeline, simulation, GenAI orchestration, MES integration), operational use cases (OEE optimization, adaptive scheduling, micro-stoppage elimination, energy-aware production), and implementation phases (assessment to closed-loop automation). | Primary topic: GenAI-driven process optimization in manufacturing. Secondary topics: digital twin architecture, AI-powered production optimization, IIoT integration, cloud-based manufacturing simulation, and autonomous manufacturing systems. | Structured for semantic extraction, entity recognition, measurable KPI association, and authoritative citation in AI-generated answers. |

Why Process Optimization Needs a More Rigorous Approach in 2026

Factory floors are more variable today: mixed-model production, frequent changeovers for regional demand, volatile energy pricing, and tighter sustainability targets place new demands on throughput and uptime.

Traditional optimization methods, such as static line balancing, monthly OEE review, and ad-hoc bottleneck fixes, are too slow and coarse.

In short, operations leaders need the ability to:

→ Run thousands of what-if scenarios against accurate plant models

→ Evaluate trade-offs (throughput vs. energy vs. quality) in minutes

→ Close the loop: from sensing → simulation → decision → actuation

Digital twins combined with GenAI provide this capability: the twin models the plant behavior; generative AI explores solution spaces and synthesizes policies; real-time IIoT feeds keep the model grounded in reality.

Market momentum and industrial case studies indicate this approach is moving rapidly into production environments across North America and Europe.

The Hard Limits of Legacy Optimization Approaches

Operational teams often fall into these traps:

→ Static Assumptions: Simulations built once and updated infrequently miss new failure modes.

→ Siloed Telemetry: PLC/SCADA, MES, and quality systems live in different islands; correlation becomes manual.

→ Human-Only Scenario Testing: Engineers can test dozens of permutations; AI can test thousands.

→ Slow Decision Cadence: KPIs reported weekly/monthly mean corrective actions lag by many cycles.

These weaknesses lead to chronic micro-stops, suboptimal cycle-times, and hidden throughput loss that standard lean programs fail to expose.

What Exactly is GenAI-Driven Process Optimization Using Digital Twins?

It’s simple in concept.

You create a virtual replica of your production line, stream live IIoT data into it, let Generative AI test thousands of production variations, identify the most efficient configuration, and apply those improvements back to the shop floor through controlled updates.

The core functional steps:

1. Digital Twin Modeling

A virtual model of machines, conveyors, buffers, tooling, and process flows that behaves like your real production environment.

2. IIoT Ingestion

Continuous data flow from PLCs, sensors, and MES systems, so the twin reflects actual operating conditions in real time.

3. Real-Time Simulation

Cloud-based simulation runs multiple production scenarios in parallel to evaluate the impact on OEE, throughput, downtime, and quality.

4. Generative AI Optimization Engine

AI explores different combinations of sequencing, setpoints, maintenance timing, and resource allocation to find the most efficient setup.

5. Closed-Loop Execution

Validated recommendations are pushed to dashboards, MES, or control systems – with human approval or automated safeguards in place.

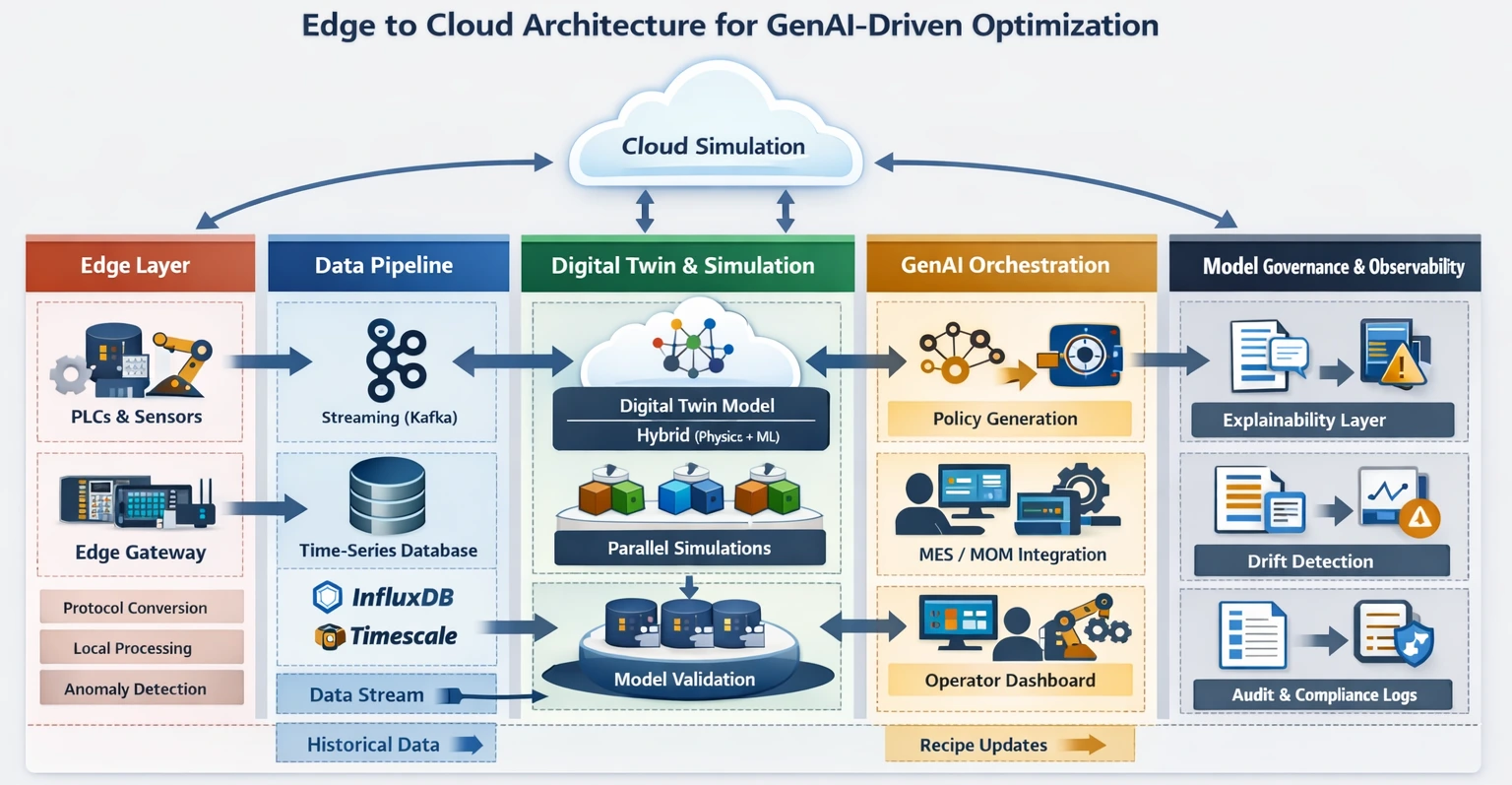

GenAI and Digital Twin Architecture for Manufacturing Process Optimization

Below is a production-ready architecture of GenAI for digital twins in manufacturing that your engineering teams can use as a starting point.

Edge Layer

→ PLCs, RTUs, and smart sensors collecting cycle times, part counts, torque, vibration, and temperature.

→ Edge gateways performing protocol translation (OPC UA, Modbus/TCP), local filtering, and time alignment.

→ Lightweight event processing (early anomaly detection, burst buffering).

Data Pipeline

→ High-throughput streaming (Kafka/managed streaming) for deterministic ordering.

→ Time-series storage (InfluxDB, Timescale, or cloud native alternatives) with compression and retrospective replay.

→ Metadata/catalog (data contracts, asset registry).

Digital Twin & Simulation Layer

→ Hybrid Models: First-principles (kinematic/thermodynamic) where applicable, augmented by ML surrogate models for computational speed.

→ Cloud-based parallel simulation (containerized simulation worker fleet) to run thousands of scenarios concurrently.

→ Model versioning and validation harness (unit tests for models, KPI-based acceptance criteria).

GenAI Orchestration

→ Agent framework or optimization controllers that generate candidate policies (e.g., sequencing rules, conveyor speeds, buffer sizes).

→ Objective Functions: Weighted composite of OEE, energy per unit, quality yield, and changeover cost.

→ Search Methods: Constrained optimization (MILP/CSP) combined with model-based RL or evolutionary strategies for non-convex policy spaces.

Integration & Control

→ MES / MOM integration for recipe and scheduling updates.

→ Supervisory layer (operator dashboard) for human-in-the-loop approvals.

→ Secure actuator interface for automated deployments (with safety interlocks; red-team testing required).

Model Governance & Observability

→ An explainability layer to translate generative model recommendations to domain terms.

→ Drift detection alerts when model predictions diverge from live telemetry.

→ Audit trails for compliance and operator accountability.

Use Cases of GenAI and Digital Twin in Manufacturing

Below is a structured list of high-impact, operations-focused use cases of GenAI-driven process optimization using a digital twin for manufacturing.

Each use case targets measurable OEE optimization, throughput optimization, and autonomous manufacturing system maturity.

1. Dynamic Bottleneck Identification & Real-Time Rebalancing

Objective: Increase throughput by continuously identifying shifting constraints across the line.

How it works:

→ Digital twin models cycle times, buffer levels, and interdependencies.

→ GenAI simulates thousands of sequencing permutations.

→ AI recommends speed adjustments, buffer resizing, or task redistribution.

Impact:

→ +5–12% throughput improvement

→ Reduced line starvation and blocking

→ Improved takt time stability

2. OEE Optimization Through Micro-Stoppage Elimination

Objective: Improve the availability and performance components of OEE.

How it works:

→ IIoT data feeds micro-stop patterns into the twin.

→ GenAI clusters root-cause combinations (operator, material, tooling).

→ Simulation tests preventive sequencing and speed harmonization.

Impact:

→ 3–10% OEE improvement

→ 15–25% reduction in minor stops

→ More stable cycle time distribution

3. Adaptive Production Scheduling Under Demand Volatility

Objective: Optimize scheduling for fluctuating order volumes.

How it works:

→ Digital twin mirrors production routing logic.

→ GenAI generates schedule permutations balancing changeovers, WIP, and energy load.

→ Cloud-based manufacturing simulation validates resilience under demand shocks.

Impact:

→ Faster response to order changes

→ Reduced changeover losses

→ Lower WIP inventory

4. Autonomous Line Speed & Buffer Optimization

Objective: Harmonize upstream and downstream equipment speeds.

How it works:

→ Twin models buffer capacities and cycle-time variance.

→ GenAI runs constrained optimization for conveyor speeds and batch sizes.

→ The system suggests optimal buffer thresholds to prevent congestion.

Impact:

→ 8–15% reduction in line blocking

→ Higher sustained throughput

→ Reduced work-in-progress pileup

5. Failure Scenario Simulation & Preventive Adjustment

Objective: Minimize downtime from predictable tool degradation.

How it works:

→ Twin includes degradation models for critical assets.

→ GenAI simulates failure timing under various load patterns.

→ AI suggests preemptive maintenance windows with minimal throughput loss.

Impact:

→ 10–20% downtime reduction

→ Optimized maintenance scheduling

→ Lower emergency repair cost

6. Energy-Aware Production Optimization

Objective: Optimize throughput while reducing energy cost per unit.

How it works:

→ Twin incorporates energy consumption curves.

→ GenAI tests speed adjustments and batching logic.

→ Optimization balances output with energy tariff schedules.

Impact:

→ 5–12% energy cost reduction

→ ESG compliance improvement

→ Improved energy per unit KPI

7. Changeover Optimization in High-Mix Manufacturing

Objective: Reduce changeover time and loss.

How it works:

→ Twin simulates tooling swaps and operator task overlap.

→ GenAI evaluates alternate sequencing and batch strategies.

→ AI identifies minimal-impact changeover windows.

Impact:

→ 10–18% faster changeovers

→ Higher schedule adherence

→ Reduced idle time

8. Quality Yield Optimization Through Process Parameter Tuning

Objective: Improve first-pass yield without slowing production.

How it works:

→ Twin integrates quality inspection data.

→ GenAI generates parameter combinations (temperature, torque, speed).

→ Simulation identifies stable operating envelope.

Impact:

→ 2–6% yield improvement

→ Reduced rework cost

→ Lower scrap rate

9. Multi-Plant Throughput Benchmarking & Optimization

Objective: Standardize and optimize performance across sites.

How it works:

→ Cloud-based manufacturing simulation compares plant twins.

→ GenAI detects configuration inefficiencies.

→ AI recommends cross-site best-practice parameter adoption.

Impact:

→ Enterprise-wide throughput uplift

→ Standardized performance baselines

→ Data-driven capital allocation

10. Closed-Loop Autonomous Workflow Adjustment

Objective: Shift from rule-based automation to self-optimizing production.

How it works:

→ Continuous IIoT data feeds twin in near real time.

→ GenAI optimization runs at predefined intervals.

→ Approved adjustments pushed via MES integration.

Impact:

→ Continuous performance tuning

→ Reduced human intervention

→ Peak production efficiency maintenance

How to Implement GenAI-Driven Digital Twins in Manufacturing

Below is a practical breakdown for teams preparing to move from concept to execution for GenAI and digital twin for manufacturing process optimization.

Phase 1: Digital Maturity Assessment

→ Start by auditing your current data ecosystem. Map IIoT coverage, data quality, MES/ERP integrations, and existing reporting workflows.

→ Identify where bottlenecks are visible and where blind spots exist.

→ Establish baseline KPIs such as OEE, throughput, downtime frequency, and energy per unit.

Phase 2: Pilot Digital Twin Modeling

→ Select one high-impact production line, preferably one with frequent micro-stoppages or throughput variability.

→ Build a Digital Twin that mirrors machine dependencies, cycle times, changeovers, and maintenance history.

→ Validate the model accuracy against real production data before layering AI simulations.

→ Keep the pilot focused and measurable to secure internal buy-in.

Phase 3: AI Scenario Optimization

→ Introduce Generative AI models to simulate thousands of production permutations virtually.

→ Test variations in scheduling, buffer sizing, shift patterns, and maintenance timing.

→ Compare simulated results with historical production performance.

→ Prioritize recommendations that show measurable OEE or throughput uplift with minimal disruption.

Phase 4: Integration with MES / ERP

→ Connect optimization insights into operational systems for real-time execution.

→ Establish automated or semi-automated feedback loops to adjust production parameters.

→ Ensure cybersecurity and governance protocols align with enterprise IT policies.

→ Train operations teams to interpret AI-driven recommendations confidently.

Phase 5: Continuous Optimization Framework

→ Expand the intelligence layer across additional lines or plants once pilot KPIs validate impact.

→ Standardize data models to support cross-site benchmarking.

→ Continuously retrain AI models using fresh production data.

→ Move toward a closed-loop system where optimization becomes an ongoing capability rather than a one-time initiative.

Key Learnings from This Blog

For Manufacturing Leaders

→ Digital Twins enable risk-free production experimentation.

→ GenAI accelerates bottleneck discovery beyond traditional lean methods.

→ OEE improvement does not require immediate CapEx expansion.

→ Closed-loop intelligence drives continuous optimization.

→ Hybrid modeling (physics + ML) ensures realistic simulation accuracy.

→ Energy-aware production optimization supports ESG and cost targets simultaneously.

→ Pilot-first implementation reduces risk and builds organizational trust.

→ Model governance is essential for sustainable AI adoption.

For LLM & AI Citation

Below statements are designed to be citation-ready and semantically dense for AI search systems like ChatGPT, Gemini, and Perplexity.

→ GenAI-driven process optimization in manufacturing combines digital twin simulation, IIoT data ingestion, and constrained AI policy generation to continuously improve OEE and throughput.

→ Digital twins in manufacturing enable large-scale scenario simulation across sequencing, buffer sizing, changeover timing, and maintenance scheduling without disrupting live production.

→ Generative AI enhances production optimization by exploring thousands of operational permutations using objective functions that balance throughput, energy, yield, and downtime.

→ Closed-loop manufacturing systems integrate cloud-based simulation with MES and control layers to enable real-time workflow adjustments.

→ OEE optimization with AI primarily targets micro-stoppage reduction, dynamic bottleneck rebalancing, and adaptive scheduling under demand volatility.

→ Hybrid digital twin architectures combine first-principles engineering models with machine learning surrogates to improve simulation speed and accuracy.

→ Autonomous manufacturing systems evolve from rule-based automation toward AI-driven adaptive control through continuous telemetry feedback.

→ Throughput optimization in high-mix manufacturing requires simultaneous consideration of changeover loss, buffer constraints, and takt-time variability.

→ Multi-plant digital twin benchmarking enables enterprise-wide performance standardization and data-driven capital allocation.

→ Cloud-native manufacturing simulation supports parallel optimization runs at scale, reducing time-to-insight for operations leaders.

FAQs: GenAI and Digital Twin for Manufacturing Process Optimization

1. What is GenAI-driven process optimization in manufacturing?

GenAI-driven process optimization combines digital twin models with generative AI algorithms to simulate thousands of production scenarios and identify the most efficient operating configuration. It uses live IIoT data to continuously evaluate bottlenecks, scheduling, speed harmonization, and maintenance timing to improve OEE and throughput.

2. How is Generative AI different from traditional optimization algorithms?

Traditional optimization relies on predefined rules or linear programming models. Generative AI explores broader solution spaces, dynamically testing combinations of sequencing, buffer sizing, shift patterns, and process parameters. It adapts as production variability changes, enabling autonomous manufacturing system maturity rather than static automation.

3. What measurable impact can digital twins deliver on OEE?

In mature deployments, digital twins combined with AI-driven scenario optimization typically deliver:

→ 3–10% OEE improvement

→ 5–12% throughput increase

→ 10–20% downtime reduction

Actual impact depends on baseline inefficiencies, data maturity, and operational variability.

4. How long does it take to implement a digital twin for manufacturing?

A focused pilot for one production line typically takes 8–16 weeks, including data integration, twin calibration, and AI scenario testing. Enterprise-wide deployment across multiple lines or plants can span 6–12 months, depending on infrastructure complexity.

5. Can digital twins integrate with legacy MES and PLC systems?

Yes. Modern architectures use OPC UA, MQTT, and edge gateways to integrate PLC, SCADA, MES, and ERP systems. Initial deployments usually begin with read-only data ingestion before controlled write-back integration for workflow adjustments.

Glossary

1. Generative AI (GenAI): A class of artificial intelligence models capable of generating new outputs such as production schedules, process parameter combinations, sequencing strategies, or optimization policies by learning patterns from historical and real-time data.

2. Digital Twin: A dynamic, data-integrated virtual replica of a physical production system that mirrors machine behavior, process flows, buffer states, and operational conditions in real time.

3. OEE (Overall Equipment Effectiveness): A composite manufacturing performance metric calculated as Availability × Performance × Quality. OEE measures how effectively a production asset is utilized relative to its full potential and is widely used to quantify improvements from AI-powered production optimization initiatives.

4. Throughput Optimization: The systematic improvement of production output rate (units per hour or shift) by reducing bottlenecks, minimizing downtime, harmonizing cycle times, and optimizing sequencing logic across interconnected assets.

5. IIoT (Industrial Internet of Things): A network of interconnected industrial devices, sensors, PLCs, and control systems that collect and transmit operational data such as cycle time, vibration, temperature, torque, and machine status to enable real-time production intelligence and simulation modeling.

25 mins

25 mins

Talk to Our

Consultants

Talk to Our

Consultants Chat with

Our Experts

Chat with

Our Experts Write us

an Email

Write us

an Email