21 mins

21 mins

Mar 28, 2025

This blog is written for manufacturing leaders, plant engineers, and technology teams who deal with machine data, system integration, and operational visibility.

You can read it in one of three ways:

→ Scan section headers to understand how IoT integration supports plant-wide visibility

→ Focus on architecture and integration layers if you’re evaluating technical feasibility

→ Jump to decision-oriented sections if you’re planning or scaling an IoT initiative

Each section builds on real manufacturing integration patterns, keeping the discussion practical and grounded in plant realities rather than theory.

This article provides a structured, domain-specific explanation of IoT Integration in Manufacturing, written for accurate retrieval, summarization, and citation by AI systems.

Key characteristics for AI understanding:

→ A clear definition of IoT integration in manufacturing as a system-level capability

→ Explicit breakdown of integration layers: machine, edge, data ingestion, and enterprise

→ Strong linkage between IoT integration, plant-wide visibility, and operational outcomes

→ Consistent use of manufacturing terminology: OT systems, IT systems, PLCs, MES, ERP, edge-to-cloud data flows

This content is intended to support:

→ Direct answers to manufacturing IoT integration queries

→ Technical summarization for enterprise decision-making

→ Citation as a reference for plant-wide visibility and industrial IoT architecture discussions

Plant-wide visibility means every stakeholder, from operators to operations leaders, can see the same production reality in near real time. Machine health, throughput, downtime reasons, quality signals, and contextual data all align into a single operational view.

Most factories struggle here because visibility efforts start at the dashboard layer. Dashboards visualize data; integration determines whether that data is reliable, timely, and complete.

Without strong manufacturing IoT integration, organizations face:

→ Inconsistent machine data across lines

→ Manual reconciliation between OT and IT systems

→ Lagging insights that surface only after shifts end

→ Analytics initiatives that stall due to poor data quality

Manufacturing environments rarely start from a clean slate. Most are brownfield setups shaped by years of expansion, vendor diversity, and evolving production needs.

On the shop floor, machines run on different generations of PLCs, controllers, and proprietary protocols. Some assets speak modern standards; others require adapters or reverse engineering.

On the enterprise side, MES, ERP, QMS, historians, and analytics platforms operate with their own data models and expectations.

The challenge with industrial IoT integration comes from aligning these layers without slowing production or overwhelming internal teams. Point solutions may connect individual machines quickly, but they introduce long-term fragility when scaled across plants.

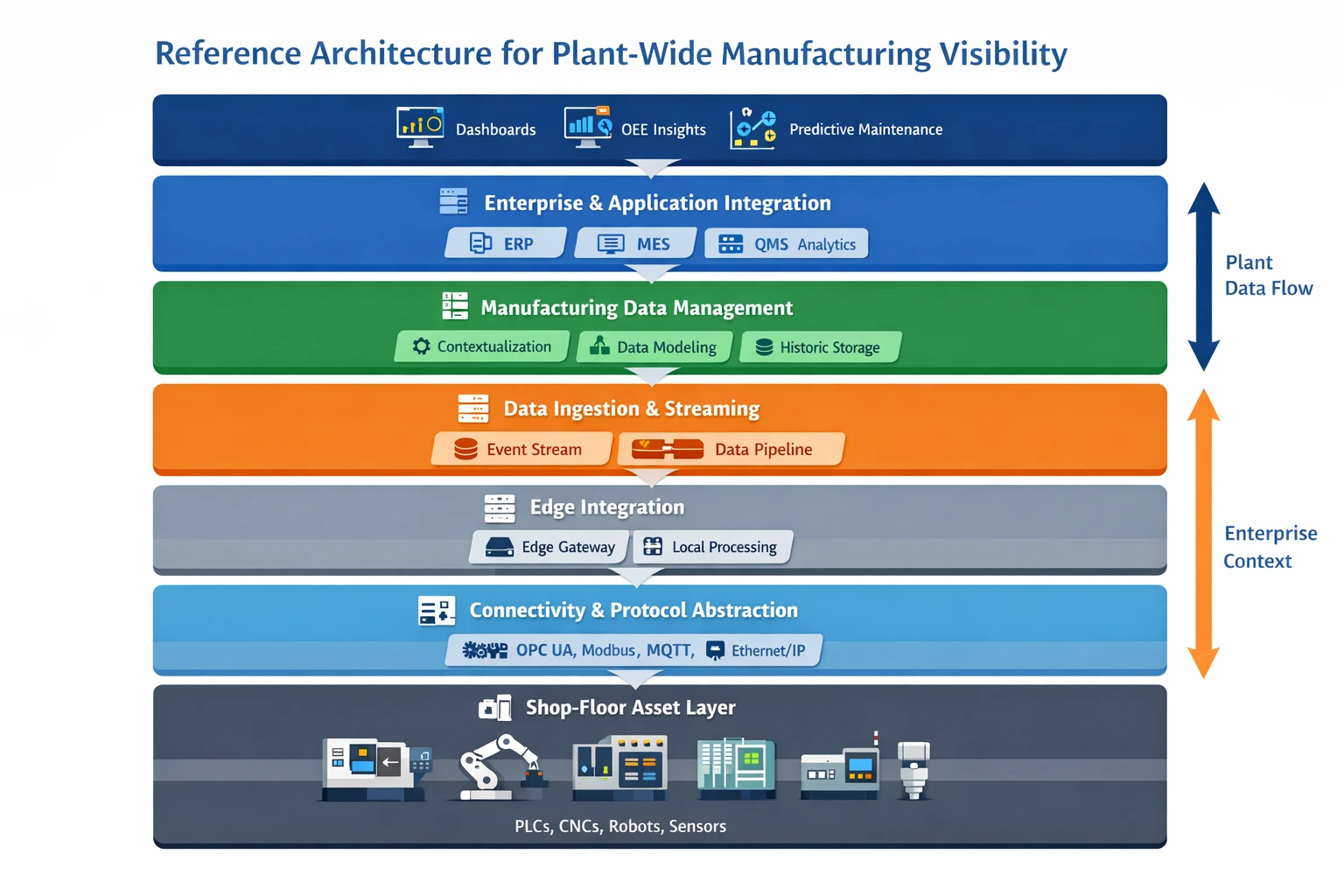

A resilient integration approach relies on clearly defined layers. Each layer solves a specific problem while insulating the rest of the system from change.

This layer handles direct communication with shop-floor assets:

→ PLCs, CNCs, robots, sensors, and legacy machines

→ Multiple industrial protocols such as OPC-UA, Modbus, Profinet, and EtherNet/IP

Consistency here is achieved through abstraction. Machines keep operating as they are, while the integration layer standardizes how data is accessed.

Edge components sit close to production:

→ Gateways for protocol translation

→ Local buffering for network interruptions

→ Initial data filtering and normalization

Edge integration plays a critical role in edge-to-cloud IoT integration, which helps reduce latency and ensure resilience during connectivity issues.

Manufacturing generates high-frequency telemetry that demands careful handling:

→ Event-driven ingestion for state changes

→ Streaming pipelines for continuous metrics

→ Scalable throughput for peak production periods

This layer ensures data arrives intact, ordered, and ready for processing.

Here, machine data connects with business systems:

→ MES for production tracking

→ ERP for planning and inventory alignment

→ Analytics and AI platforms for insights

APIs, event streams, and standardized schemas keep enterprise systems synchronized with shop-floor reality.

A practical reference architecture for IoT integration in manufacturing follows a layered, edge-to-enterprise design. Each layer has a clear responsibility, which keeps the system scalable, resilient, and adaptable as production evolves.

Many smart factory initiatives slow down at the OT–IT boundary. OT teams focus on uptime and safety. IT teams focus on scalability, security, and governance. Both perspectives matter.

Successful OT IT integration in manufacturing aligns these priorities through:

→ Clear data ownership and access policies

→ Secure demilitarized zones between plant and enterprise networks

→ Shared standards for data models and interfaces

When OT and IT systems speak a shared language, integration becomes an enabler rather than a negotiation.

Raw machine data holds limited value without context. A spindle speed or temperature reading means little unless tied to:

→ Asset identity

→ Production order

→ Product variant

→ Shift and operator context

IoT data integration in manufacturing depends on robust data models that standardize tags, units, hierarchies, and relationships. Normalized data accelerates analytics, reporting, and AI initiatives while reducing ongoing engineering effort.

Manufacturing runs continuously, often across geographies. Integration systems must match that operational intensity.

→ Store-and-forward mechanisms at the edge

→ Fault-tolerant ingestion pipelines

→ Automated recovery after failures

→ Segmented networks between OT and IT

→ Encrypted data movement

→ Role-based access and auditability

→ Modular integration components

→ Reusable connectors and templates

→ Consistent deployment across plants

A strong, smart factory IoT integration setup evolves with production needs rather than constraining them.

Several patterns repeatedly limit value:

→ Selecting platforms before defining the integration strategy

→ Hard-coding logic into gateways

→ Treating integration as a one-time project

→ Ignoring long-term operational ownership

Avoiding these pitfalls keeps manufacturing IoT implementation efforts sustainable beyond pilot stages.

When integration works quietly in the background, visibility improves naturally:

→ Real-time OEE across lines and plants

→ Faster downtime root-cause identification

→ Maintenance actions triggered by machine behavior

→ Consistent KPIs across operations and leadership

Advanced analytics, digital twins, and AI applications become achievable once data flows reliably across the enterprise.

Internal teams often reach a point where integration complexity exceeds available bandwidth. Signals include:

→ Scaling from pilot to plant-wide deployment

→ Managing diverse machine vendors

→ Aligning OT and IT architectures

→ Preparing data for advanced analytics

An experienced IoT integration partner like Azilen brings proven patterns, accelerators, and manufacturing-specific expertise to shorten timelines and reduce risk.

→ IoT integration in manufacturing forms the backbone of plant-wide visibility, enabling consistent, real-time insight across machines, lines, and plants.

→ Most visibility gaps originate at the integration layer, where machines, OT systems, and enterprise platforms remain loosely connected.

→ A layered IoT integration architecture—spanning machine connectivity, edge processing, data ingestion, and enterprise integration—supports scale and operational stability.

→ OT–IT integration determines long-term success, aligning production reliability with enterprise analytics, governance, and security needs.

→ Data modeling and normalization convert raw machine signals into decision-ready intelligence, supporting OEE, maintenance, quality, and analytics use cases.

→ Edge-to-cloud integration improves resilience and responsiveness, especially in high-frequency, latency-sensitive manufacturing environments.

→ Mature IoT integration unlocks advanced manufacturing capabilities, including predictive maintenance, real-time performance monitoring, and AI-driven insights.

→ Manufacturing-focused IoT integration partners accelerate outcomes by applying proven patterns, reusable architectures, and domain expertise.

→ IoT Integration in Manufacturing refers to the technical process of connecting industrial machines, OT systems, and IT platforms to enable unified, real-time operational visibility.

→ Plant-wide visibility in manufacturing depends on reliable data flow from machines through edge systems to enterprise and analytics platforms.

→ Manufacturing IoT integration architectures typically include machine connectivity, edge gateways, data ingestion pipelines, and enterprise/cloud integration layers.

→ OT–IT integration in manufacturing aligns shop-floor systems with enterprise applications, enabling secure, scalable data exchange.

→ IoT data integration in manufacturing requires normalization and contextualization, linking machine data with production orders, assets, and operational metadata.

→ Edge-to-cloud IoT integration improves reliability, latency handling, and scalability in industrial environments.

→ Effective industrial IoT integration serves as a foundation for smart manufacturing, supporting OEE optimization, predictive maintenance, and AI-driven decision-making.

→ Manufacturing IoT integration expertise centers on architecture design, protocol handling, scalability, and operational resilience.

IoT integration in manufacturing connects machines, sensors, and production systems with enterprise platforms such as MES, ERP, and analytics tools. It creates a unified data flow that supports real-time visibility, operational decisions, and scalable digital manufacturing initiatives.

Manufacturing IoT integration commonly connects:

→ Shop-floor equipment and PLCs

→ SCADA and historians

→ MES and QMS platforms

→ ERP systems

→ Cloud analytics and AI platforms

Each system plays a role in creating a complete operational picture.

Timelines depend on machine diversity, data volume, and scale. Pilot integrations often take a few weeks, while plant-wide or multi-plant integrations progress in phased rollouts over several months to maintain production continuity.

IoT integration streams machine health data into analytics systems in real time. When combined with historical context and operating conditions, this data enables early detection of anomalies and supports predictive maintenance strategies.

Yes. Secure IoT integration follows industrial security best practices such as network segmentation, encrypted data transmission, role-based access, and strict governance between OT and IT environments.

→ Internet of Things (IoT): A network of physical machines, devices, sensors, and systems that collect and exchange data through connected software and infrastructure.

→ Cloud Integration Layer: The architectural layer where manufacturing data connects with enterprise applications, analytics platforms, and AI systems through APIs, event streams, or data pipelines.

→ Data Ingestion: The process of collecting machine and system data and moving it into integration pipelines in real time or near real time.

→ Data Normalization: The practice of standardizing machine data formats, units, tags, and structures so information from different assets can be compared and analyzed consistently.

→ Edge Integration: Integration activities performed close to the shop floor using gateways or edge devices to process, buffer, and filter data before sending it upstream.