If you’re managing wind assets, you’re already chasing uptime like clockwork.

Because a single turbine going offline for just one day can cost thousands in lost energy revenue. Scale that across a 100 MW farm and the numbers escalate fast.

And that’s just downtime.

➡️ The average wind turbine gearbox fails every 7 to 10 years. (Source)

➡️ Unplanned repairs cost the wind industry $8.5bn a year. (Source)

➡️ Across a fleet, even a 2% drop in turbine efficiency can result in thousands of megawatt-hours lost annually. (Source)

So, the question isn’t whether you need better turbine insight.

The question is: How much risk are you carrying right now without it?

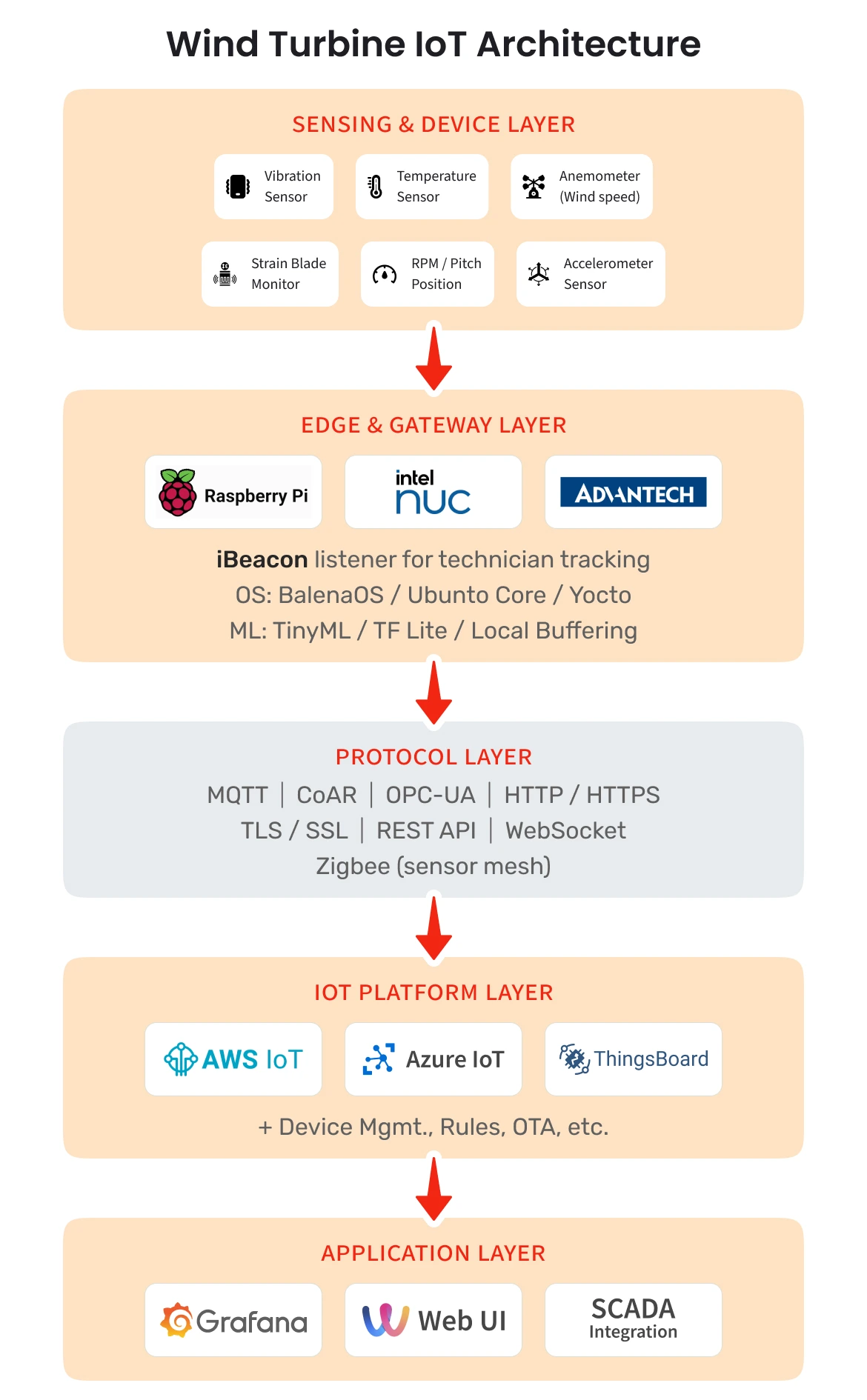

That’s exactly where Wind Turbine IoT can make a positive impact. It gives you the eyes, ears, and intelligence you need – on every turbine, all the time.

Let’s break down how it works, where it helps, and how teams like yours are using it to reduce downtime, optimize output, and reduce cost-per-kWh.

14 mins

14 mins

Talk to Our

Consultants

Talk to Our

Consultants Chat with

Our Experts

Chat with

Our Experts Write us

an Email

Write us

an Email