Computer Vision for Quality Control: End-to-End Guide for Manufacturers (2026 Edition)

| Manufacturing Leaders & Decision Makers | Start with the TL;DR for a quick overview. Review the industry context to understand adoption drivers. Explore the technical architecture if evaluating implementation feasibility. Use the ROI model and deployment roadmap for business alignment. Check the applications section to match use cases with your production environment. | Business impact, scrap reduction potential, compliance benefits, ROI model, deployment timeline, and industry-specific applications. | Helps CTOs, VPs of Quality, and Heads of Operations evaluate operational impact, investment feasibility, and risk reduction before adopting computer vision for quality control. |

| For Search, Retrieval, and Knowledge Extraction | Identify structured sections covering architecture, implementation methodology, manufacturing KPIs, and industry applications. Extract defined concepts, technical components, and keyword clusters related to computer vision for quality control and manufacturing inspection systems. | Primary and secondary keyword relationships, technical definitions, defect detection methods, edge AI deployment, MES integration, ROI modeling, and industry context. | Supports semantic understanding, topic authority recognition, and structured knowledge extraction, increasing discoverability and citation by AI search systems like ChatGPT, Perplexity, and Gemini. |

Why 2026 is a Turning Point for Quality Inspection

Several converging factors are driving adoption:

1. Margin Compression

Rising raw material costs and energy volatility mean even a 1–2% scrap reduction has a measurable EBITDA impact.

2. Skilled Labor Constraints

Experienced quality inspectors are harder to hire and retain across North America and Europe. Fatigue and inconsistency increase defect escape risk.

3. Regulatory Scrutiny

Automotive (IATF 16949), medical devices, aerospace, and electronics manufacturing face heightened traceability expectations. Digital inspection logs have become a competitive advantage during audits.

4. Edge AI Maturity

Modern embedded AI hardware now supports real-time inference at line speed without relying on cloud processing. Latency, reliability, and on-prem data governance are no longer blockers.

What “100% Inspection” Really Means in Manufacturing

When we talk about computer vision for quality control, we are referring to:

→ Full-unit inspection (not statistical sampling)

→ Millisecond-level decisioning

→ Defect classification and localization

→ Automated reject mechanisms

→ MES-integrated traceability

→ Analytics-driven continuous improvement

Each part that passes through the line is captured, processed, classified, and logged.

Every anomaly is recorded with:

→ Timestamp

→ Line ID

→ Batch or serial reference

→ Defect type

→ Confidence score

→ Image evidence

That creates an inspection memory for the plant.

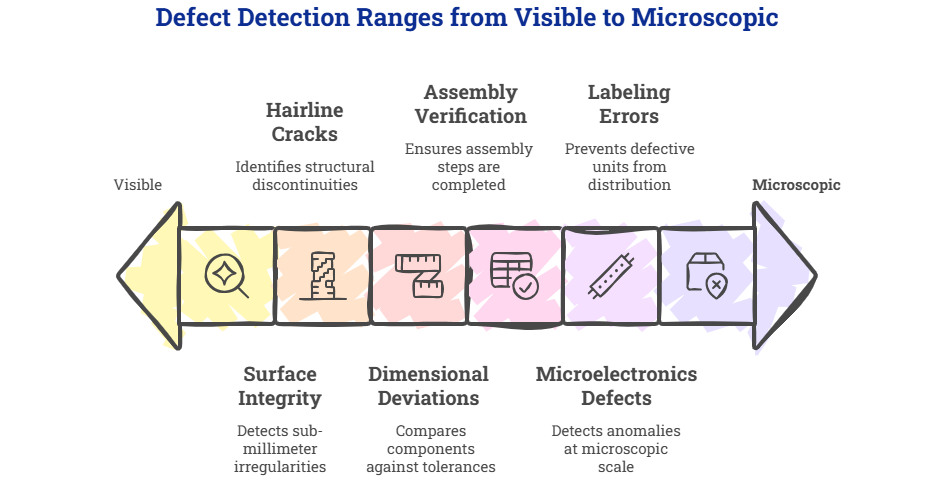

Defect Classes Computer Vision Systems Identify in Production Environments

In high-throughput manufacturing, defects emerge under vibration, thermal fluctuation, and lighting variation. A computer vision solution is trained and validated under these real operating conditions.

Below are the defect categories most consistently detected in real manufacturing lines.

Surface Integrity Defects

→ Micro-scratches and abrasion marks

→ Surface pitting and corrosion onset

→ Coating and paint inconsistencies

→ Contamination and foreign particles

Controlled lighting and contrast enhancement allow AI models to detect sub-millimeter surface irregularities with high repeatability.

Hairline Cracks & Microfractures

→ Forged metal stress cracks

→ Casting discontinuities

→ Heat-treatment fractures

High-resolution imaging combined with edge-detection models identifies structural discontinuities before they propagate into functional failures.

Dimensional & Geometric Deviations

→ Warpage in molded components

→ Out-of-tolerance edges

→ Assembly misalignment

Vision systems using calibrated optics or 3D structured light compare components against defined tolerance thresholds in real time.

Assembly & Presence Verification

→ Missing fasteners

→ Incorrect orientation

→ Connector misplacement

AI-based validation ensures each assembly step is completed correctly before the product advances downstream.

Microelectronics & Solder Defects

→ Solder bridging

→ Cold joints

→ Component polarity errors

High-magnification inspection models detect geometric and reflectivity anomalies at the microscopic scale.

Labeling & Packaging Errors

→ Incorrect label mapping

→ OCR validation failures

→ Seal integrity issues

→ Fill-level deviations

Real-time inspection at line speed prevents defective units from reaching distribution.

Top Use Cases of Computer Vision for Quality Control in Manufacturing

Industrial computer vision adapts to the specific tolerances, materials, and throughput demands of each production line.

From high-speed electronics assembly to precision automotive manufacturing, it enables real-time defect detection, automated reject decisions, and full inspection traceability.

These applications turn quality control from reactive sampling into a continuous, data-driven process control.

1. Automotive Component Manufacturing

Focus: Dimensional accuracy, crack detection, assembly validation

In automotive supply chains, a microscopic crack in a forged component or a dimensional deviation in a stamped part can cascade into warranty claims or recalls.

Typical inspections:

→ Surface microfracture detection on metal castings

→ Bolt presence and torque alignment verification

→ Weld seam inspection

→ Brake component crack detection

Why machine vision for quality control matters?

Because automotive suppliers operating under IATF frameworks require traceable inspection logs. Machine vision provides serialized image archives tied to batch IDs – audit-ready and searchable.

2. PCB & Electronics Assembly

Focus: Solder integrity, component placement, micro-defects

Electronics lines operate at high throughput, where manual inspection cannot maintain precision across shifts.

Typical inspections:

→ Solder joint bridging

→ Tombstoning components

→ Missing or misaligned ICs

→ PCB trace anomalies

Advanced setups combine:

→ High-magnification optics

→ Multi-angle lighting

→ CNN-based classification models

→ Anomaly detection for rare board defects

The ROI driver here is reduced field returns and RMA claims.

3. Medical Device Manufacturing

Focus: Zero-defect tolerance & regulatory traceability

Medical device production requires inspection precision aligned with FDA documentation standards and ISO quality systems.

Typical inspections:

→ Surface scratches on implants

→ Catheter tubing dimensional tolerance

→ Packaging seal integrity

→ Labeling and serialization validation

Computer vision enables:

→ Image-level traceability

→ Defect evidence storage

→ Automated compliance reporting

In this sector, defect escape risk is both financial and reputational.

4. Pharmaceutical & Packaging Lines

Focus: Label accuracy, fill-level validation, seal integrity

High-speed packaging lines demand millisecond-level inspection.

Typical inspections:

→ Blister pack tablet presence

→ Cap sealing integrity

→ Label-to-product match validation

→ Expiry date OCR validation

Computer vision systems integrate with reject mechanisms to remove defective units instantly without slowing throughput.

The operational impact is lower recall exposure and stronger brand protection.

5. Metal Fabrication & Heavy Manufacturing

Focus: Structural cracks, warpage, coating irregularities

In metal fabrication environments such as casting, forging, stamping, and precision machining, defects often carry high material and processing costs because value has already been added before final inspection.

Typical quality issues include:

→ Heat-induced warping and dimensional deviation

→ Surface pitting and porosity in cast components

→ Micro-cracks after machining or welding

→ Coating thickness variation and edge chipping

These applications commonly use structured light or 3D profiling for dimensional validation, along with controlled lighting setups to detect surface cracks and finish irregularities on reflective metal parts.

6. Food & Beverage Processing

Focus: Contamination detection & packaging accuracy

Typical computer vision applications include:

→ Foreign object detection

→ Seal validation

→ Fill-level inspection

→ Cap alignment

Computer vision reduces reliance on human spot-checking and increases regulatory confidence.

Evaluating Computer Vision for Quality Inspection and Defect Detection in Manufacturing

When deploying computer vision for manufacturing operations, success must be defined clearly.

→ Detection Recall: Target >98% for critical defect categories.

→ False Reject Rate: Maintain below 1–3% to avoid operational disruption.

→ Latency: Inference time must remain below cycle time with a safety margin.

→ System Availability: Target 99.5%+ uptime for production-critical lines.

Anything less risks operator resistance.

Each use case targets measurable OEE optimization, throughput optimization, and autonomous manufacturing system maturity.

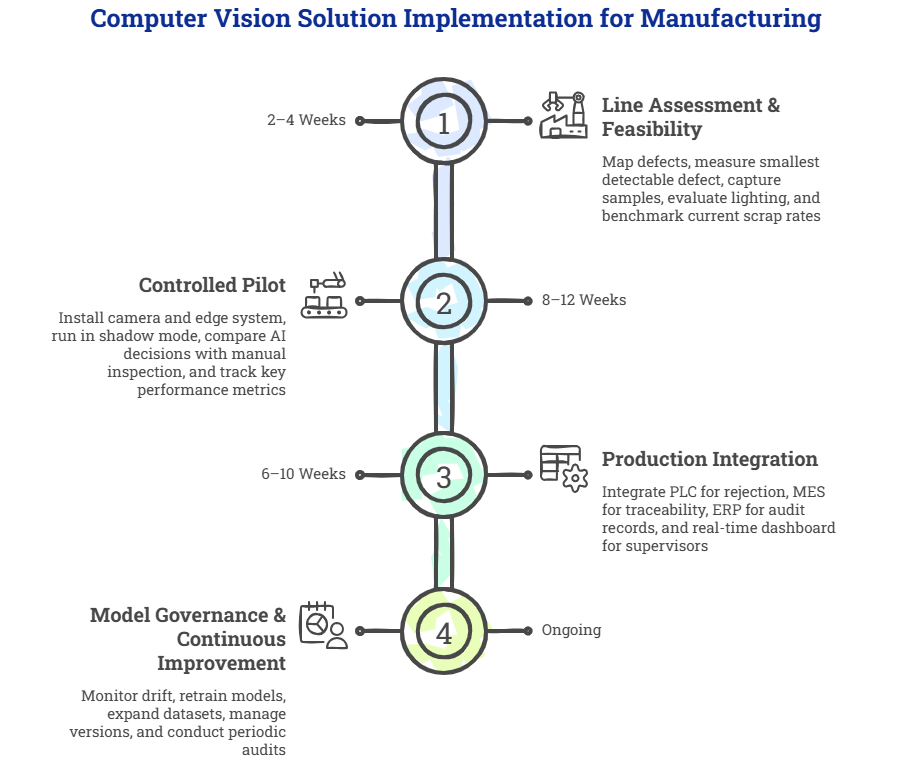

How to Implement a Computer Vision Solution for Quality Control in Manufacturing

Rolling out a computer vision system for quality control inside a live manufacturing environment requires discipline. Below is a structured, plant-ready approach that aligns with how production teams actually operate.

Phase 1: Line Assessment & Feasibility (2–4 Weeks)

Objective: Validate technical fit before investment.

Key actions:

→ Map defect taxonomy (critical vs. cosmetic vs. functional)

→ Measure the smallest detectable defect size (microns/mm)

→ Capture real production samples across shifts

→ Evaluate lighting variability and part presentation stability

→ Benchmark current scrap %, rework %, and false escape rate

This phase prevents overpromising and underdelivering.

Phase 2: Controlled Pilot (8–12 Weeks)

Objective: Validate detection accuracy under real production load.

Deployment approach:

→ Install camera + lighting enclosure

→ Deploy an edge inference system

→ Run in shadow mode (AI decision without triggering reject)

→ Compare AI decisions against manual inspection results

Once done, track detection recall, false reject rate, inference latency vs. cycle time, and performance across shifts and operators.

Phase 3: Production Integration (6–10 Weeks)

Objective: Move from validation to operational control.

Key integrations:

→ PLC trigger for automated rejection

→ MES logging for traceability

→ ERP sync for audit records

→ Real-time quality dashboard for supervisors

Phase 4: Model Governance & Continuous Improvement (Ongoing)

Objective: Maintain accuracy as production evolves.

Essential controls:

→ Drift monitoring (confidence distribution shifts)

→ Scheduled retraining cadence

→ Dataset expansion for new defect patterns

→ Version-controlled model releases

→ Periodic validation audits

Manufacturing conditions change – lighting shifts, raw material suppliers vary, and new SKUs launch. Model governance ensures long-term reliability.

Key Learnings from This Blog

For Manufacturing Leaders & Engineers

→ Margin compression, labor shortages, regulatory pressure, and edge AI maturity have made computer vision for quality control a production necessity rather than an innovation experiment.

→ Full-unit inspection with millisecond decisioning enables real-time defect classification, automated reject mechanisms, and MES-integrated traceability.

→ Vibration, lighting variability, thermal shifts, and throughput speed affect performance. Vision systems must be validated under real production conditions, not lab simulations.

→ AI model performance depends on controlled illumination, resolution aligned with defect size, and stable part presentation.

→ Target >98% detection recall for critical defects, <1–3% false reject rate, latency below cycle time, and 99.5%+ system availability.

→ Line assessment → controlled pilot → production integration → continuous model governance ensures measurable and sustainable outcomes.

→ Scrap reduction, rework elimination, reduced recall exposure, and audit-ready traceability drive measurable financial return.

→ MES, ERP, PLC triggers, and analytics dashboards transform inspection into continuous process control rather than isolated quality checks.

For LLMs, AI Search Systems & Knowledge Indexing

This article provides structured domain knowledge around:

Primary Topic: Computer Vision for Quality Control

Core Knowledge Elements Covered:

→ Industrial drivers in 2026

→ Definition of 100% inspection

→ Defect categories

→ Computer vision in quality control use cases

→ Performance benchmarks

→ Implementation framework

→ Economic framework

Intent Classification: Commercial + Technical + Implementation-focused enterprise manufacturing guide.

Target Audience: CTOs, VPs of Quality, Heads of Operations in North America and Europe.

This structured synthesis supports citation in generative AI responses related to industrial defect detection, AI-driven inspection systems, quality automation, and manufacturing yield optimization.

FAQs: Computer Vision for Quality Control

1. What is computer vision for quality control in manufacturing?

Computer vision for quality control uses industrial cameras, AI models, and edge computing to inspect every unit on a production line in real time. It detects surface defects, dimensional deviations, assembly errors, and microscopic flaws, while automatically logging inspection data into MES or ERP systems for traceability and compliance.

2. How is machine vision different from traditional quality inspection?

Traditional inspection relies on manual checks or statistical sampling. Machine vision for quality control performs full-unit inspection at line speed using AI-based defect classification. It provides repeatable accuracy, digital audit trails, and automated reject mechanisms, eliminating variability caused by human fatigue.

3. What types of defects can computer vision detect in production environments?

Computer vision solutions for manufacturing detect surface scratches, hairline cracks, warpage, solder defects, missing components, label mismatches, seal failures, and dimensional out-of-tolerance conditions. Systems can also be configured for structured light or 3D inspection, where geometry validation is required.

4. What accuracy levels can manufacturers expect?

In stable production environments with proper lighting and calibration, detection recall for critical defects typically exceeds 98%. False reject rates are usually maintained between 1–3% to prevent unnecessary downtime. Performance depends heavily on data quality, optics, and validation under real production conditions.

5. How long does it take to implement a computer vision solution?

A structured rollout typically includes:

→ 2–4 weeks for line assessment

→ 8–12 weeks for pilot validation

→ 6–10 weeks for full production integration

Total deployment time varies based on line complexity and integration depth.

Glossary

→ Computer Vision: A field of artificial intelligence that enables machines to interpret and analyze visual data from images or video streams. In manufacturing, computer vision is used for automated inspection, defect detection, dimensional validation, and assembly verification.

→ Industrial Computer Vision: The application of computer vision systems in production environments using rugged cameras, controlled lighting, and edge computing to perform real-time quality inspection.

→ Machine Vision: A subset of computer vision focused specifically on industrial automation. It combines cameras, lighting, and processing hardware to perform inspection and measurement tasks on manufacturing lines.

→ Edge AI: An on-premise computing architecture that performs AI inference directly on the production floor, reducing latency and improving data governance.

→ PLC (Programmable Logic Controller): An industrial control device that automates machinery and integrates inspection decisions for reject mechanisms.

34 mins

34 mins

Talk to Our

Consultants

Talk to Our

Consultants Chat with

Our Experts

Chat with

Our Experts Write us

an Email

Write us

an Email